Earthwork for Mission-Critical & Heavy Industrial Scale

We deliver massive-scale site preparation for the most demanding projects in the Southwest. From moving millions of cubic yards for hyperscale data centers to executing deep-trench utility excavations in complex geology, our fleet and team are built for magnitude. We don't just move dirt; we engineer the foundation for billion-dollar infrastructure. Whether it’s rapid mass excavation or surgical cuts for underground vaults, we maintain schedule certainty in high-pressure environments.

Earthwork Expertise – Pinnacle Heavy Civil

The Foundation of Every Megawatt-Ready Site

At Pinnacle Heavy Civil, earthwork isn’t a line item — it’s the make-or-break phase that turns raw Arizona desert into laser-level, gigawatt-capable campuses for the world’s largest AI and hyperscale operators.

1. Cut and Fill: The Physics of Volume and Density

"Cut and fill" is the process of moving earth from high points (cut) to low points (fill) to create a level building pad. While it looks like simple logistics, it is governed by the physics of soil states.

The Science: Shrink and Swell Factors

Soil changes volume depending on its state. You cannot simply move 1 cubic yard of dirt from a hole and expect it to fill a 1 cubic yard void. This is because of the Void Ratio , which is the ratio of the volume of voids (air/water) to the volume of solids.

Bank Cubic Yards (BCY): Soil in its natural, in-situ state.

Loose Cubic Yards (LCY): Soil after it has been excavated. It "swells" because the mechanical action introduces air, increasing the void ratio. (Clay can swell 20–40%).

Compacted Cubic Yards (CCY): Soil after it has been pounded into place. It "shrinks" as air is forced out.

The Engineering Challenge:

Grading plans must account for the Shrinkage Factor. If you excavate 1,000 yards of soil, you might only get 850 yards of compacted fill because you are packing the particles tighter than nature did.

2. Over-excavation & Re-compaction: Soil Mechanics

This is often the most confusing part for clients: "Why are you digging a hole just to put the dirt back in?"

The "Why": Homogeneity and Liquefaction

Native soil is geologically random. It contains:

Stratification: Layers of soft clay sandwiched between hard sand.

Biomass: Decaying roots that leave voids (holes) when they rot.

Collapsible Soils: Dry, loose soils that rapidly consolidate (shrink) when they get wet.

By over-excavating, we destroy the unreliable native structure and replace it with a remolded, homogeneous engineered fill.

The Science: The Proctor Curve

Re-compaction is not just about smashing dirt; it is about chemistry and friction. The goal is to achieve Maximum Dry Density (MDD).

To get soil particles to pack tightly, you need lubrication.

Too Dry: Friction between particles is too high; they won't slide past each other to fill voids.

Too Wet: Water is incompressible. If the voids are full of water, the soil particles cannot touch. This creates a "pumping" effect where the ground feels like a waterbed.

Optimum Moisture Content (OMC): This is the specific percentage of water that provides just enough lubrication for particles to slide into a dense interlocking arrangement without hydro-locking.

Engineers test this using a Nuclear Density Gauge, measuring against the laboratory Proctor standard. We generally look for 95% Relative Compaction,

3. Dust Control & SWPPP: Fluid Dynamics and Cohesion

Dust control and SWPPP (Stormwater Pollution Prevention Plan) are about managing the movement of particles through air and water.

Dust Control: Surface Tension and Cohesion

Dust consists of fine particulates (PM10 and PM2.5). When heavy machinery grinds soil, it breaks the cohesive bonds holding these particles together.

Water trucks aren't just wetting the ground; they are re-introducing Surface Tension. Water molecules adhere to soil particles and to each other (cohesion), increasing the mass of the particles so they are too heavy to become airborne by wind or tire friction.

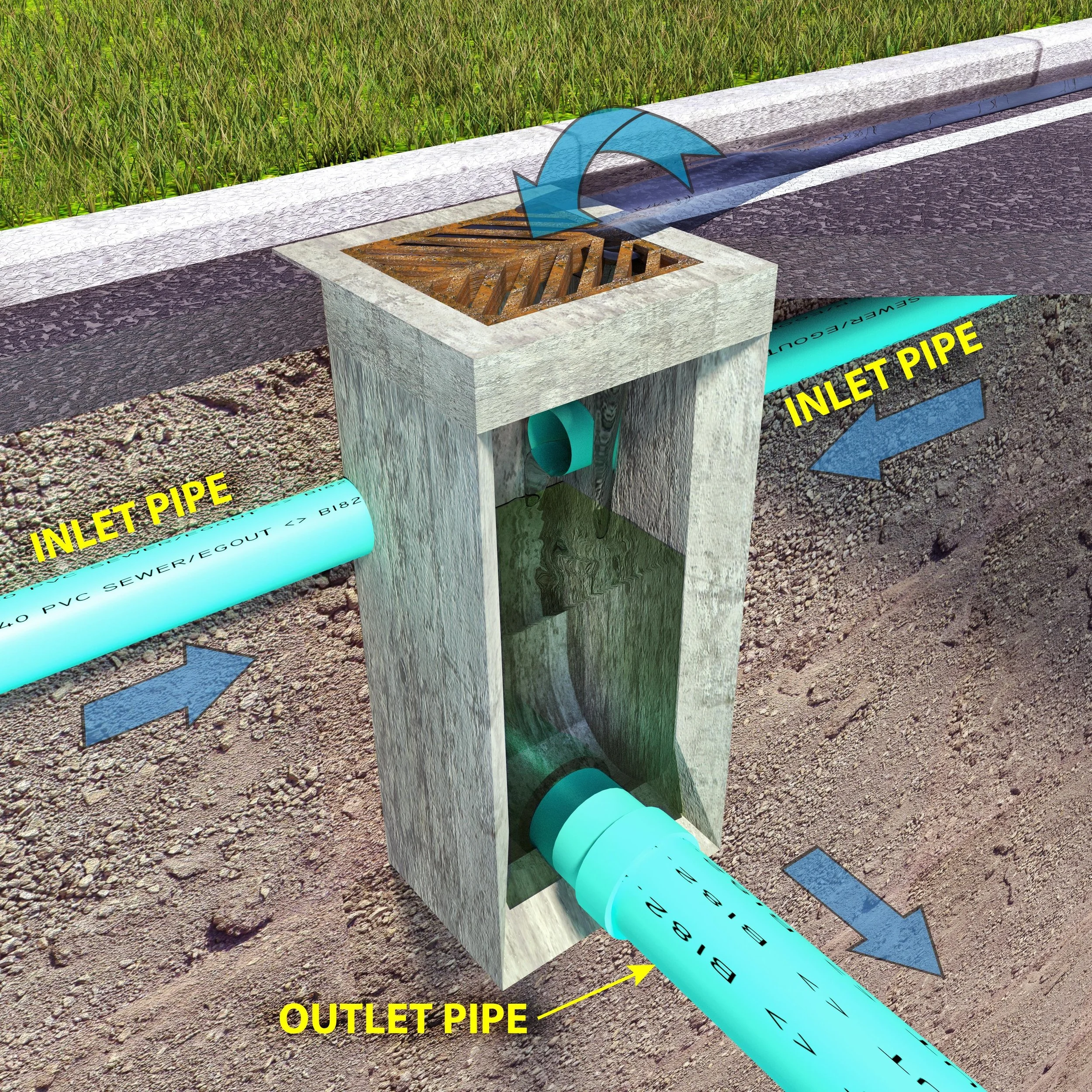

SWPPP: Erosion and Sedimentation

This involves the physics of Fluid Dynamics.

Velocity determines carrying capacity: Fast-moving water has high kinetic energy, capable of picking up and carrying soil (erosion).

Sedimentation: When water slows down, it loses energy, and gravity takes over, causing soil to drop out of suspension.

SWPPP Devices (Wattles, Silt Fences, Basins):

These do not "filter" the water; they rely on the velocity reduction principle. By placing an obstacle (like a wattle) in the flow path, we force the water to slow down (pond). As velocity drops ($v \to 0$), the sediment settles to the bottom before the water flows over the barrier.

1. The Reaction: Hydration (Growing Crystals)

Concrete is a mixture of paste (cement + water) and aggregates (sand + rock). The paste is the glue; the aggregates are the filler.

The Science: Exothermic Crystalline Growth

When water hits Portland cement, it triggers an Exothermic Reaction (it generates heat).

The Gel: As mentioned in soil stabilization, the cement grains dissolve and grow spiky crystals called Calcium-Silicate-Hydrate (C-S-H) gel.

The Interlock: These microscopic spikes grow outward, latching onto the sand and gravel, and interlocking with each other. This turns the liquid soup into a solid rock.

The "Set": The initial "set" happens when these crystals touch for the first time. But the reaction continues for years as long as moisture is present.

2. The Golden Rule: Water-Cement Ratio (w/c)

This is the single most important number in concrete science. It dictates strength and durability.

The Physics: Space and Voids

Water has volume.

Necessary Water: You only need a w/c ratio of about 0.25 to chemically hydrate all the cement.

Convenience Water: We usually mix at 0.45 to 0.50. Why? Because 0.25 mix is dry and unworkable. We add extra water just to make it flow (slump) so workers can place it.

The Cost of Flow: The extra water eventually evaporates. When it leaves, it leaves behind Capillary Pores (microscopic air voids).

The Rule: More Water = More Voids = Weaker Concrete. Every extra gallon of water you add to the truck weakens the final product and increases cracking.

Modern Solution: We use Superplasticizers (Admixtures). These are chemicals that impart an electrical charge to cement grains, causing them to repel each other. This makes the concrete flow like a liquid without adding extra water.

3. Reinforcement: The Perfect Marriage

Concrete has a fatal flaw: It is strong in Compression (being squashed) but terrible in Tension (being pulled apart).

Compressive Strength: ~4,000 psi (Strong).

Tensile Strength: ~400 psi (Weak—only about 10% of compressive strength).

The Science: The Composite Beam

To fix this, we insert steel (rebar).

The Beam Theory: When you load a beam (like a floor slab), the top tries to squash (Compression) and the bottom tries to rip apart (Tension).

The Load Transfer: The concrete handles the crushing force at the top. The steel handles the pulling force at the bottom.

The Miracle of Physics: Steel and Concrete have almost the exact same Coefficient of Thermal Expansion.

If they expanded at different rates when it got hot, the steel would shatter the concrete from the inside. Because they expand together, they act as one material.

4. Curing: The Critical Timeline

"Curing" is the maintenance of adequate moisture and temperature to allow hydration to continue.

The Physics: Plastic Shrinkage

The most dangerous time for concrete is the first 24 hours.

Evaporation vs. Bleed: As concrete settles, water "bleeds" to the surface. If the sun/wind evaporates surface water faster than the bleed water can replace it, the surface dries out and tears. These are Plastic Shrinkage Cracks.

Why we wet cure: By flooding the slab or using curing blankets, we trap the moisture inside. This forces the water to react with the cement rather than evaporating into the atmosphere.

The 7-Day vs. 28-Day Rule:

7 Days: Concrete reaches ~70% of its strength.

28 Days: The industry standard benchmark for 100% design strength

5. Pre-stressing vs. Post-Tensioning

Sometimes standard rebar isn't enough. We need Active Reinforcement.

The Science: The "Rubber Band" Effect

Imagine a row of books on a shelf. If you lift them, they fall apart. If you squeeze the ends together tight, you can lift the whole row as one unit.

Post-Tensioning (PT): We lay cables (tendons) inside the concrete. Once the concrete cures, we pull the cables tight (tension them) to 33,000 lbs of force and lock them off.

The Physics: This puts the entire slab into a permanent state of Compression. Since concrete is strongest in compression, this makes the slab incredibly strong and prevents cracks from ever opening up (because the cable is constantly squeezing them shut).

Here is a "Red Flag" checklist for reviewing a Geotechnical Report. This document is often 50+ pages of data, but these specific sections dictate your budget and schedule.

Use this to spot costly requirements hidden in the engineering jargon.

1. The "Over-Ex" Requirement (The Big Cost Driver)

Where to look: Recommendations Section > Earthwork / Grading

Check: Does it require "over-excavation and re-compaction"?

The Red Flag: If the report specifies digging 5+ feet below existing grade or 5+ feet below footings.

Why it matters: Every foot of depth multiplies the volume of dirt you have to touch. If you have to dig out 5 feet of dirt across a 20,000 sq. ft. pad, you are moving ~3,700 cubic yards just to put it back. That is a massive line item in the budget.

2. Expansive Soil Potential (The "Heaving" Risk)

Where to look: Lab Results > Atterberg Limits / Expansion Index (EI)

Check: Look for the Plasticity Index (PI) or Expansion Index (EI).

The Red Flag:

PI > 15-20: Indicates highly expansive clay.

EI > 50: Indicates medium to high expansion potential.

Why it matters: High numbers mean the soil acts like a sponge (swells when wet). This forces you to either:

Import non-expansive fill (expensive).

Upgrade the foundation to a Post-Tensioned (PT) slab or mat foundation (expensive).

Chemically treat the soil with lime (complex).

3. Soluble Sulfates (The "Concrete Killer")

Where to look: Corrosivity / Chemical Analysis

Check: The percentage of water-soluble sulfates.

The Red Flag: Sulfate content above 0.10% or 1,000 ppm.

Why it matters: Sulfates in the soil attack the chemistry of standard concrete, causing it to crumble over time. If high sulfates are found, you must switch to Type V cement (sulfate-resistant), which can have longer lead times and higher costs.

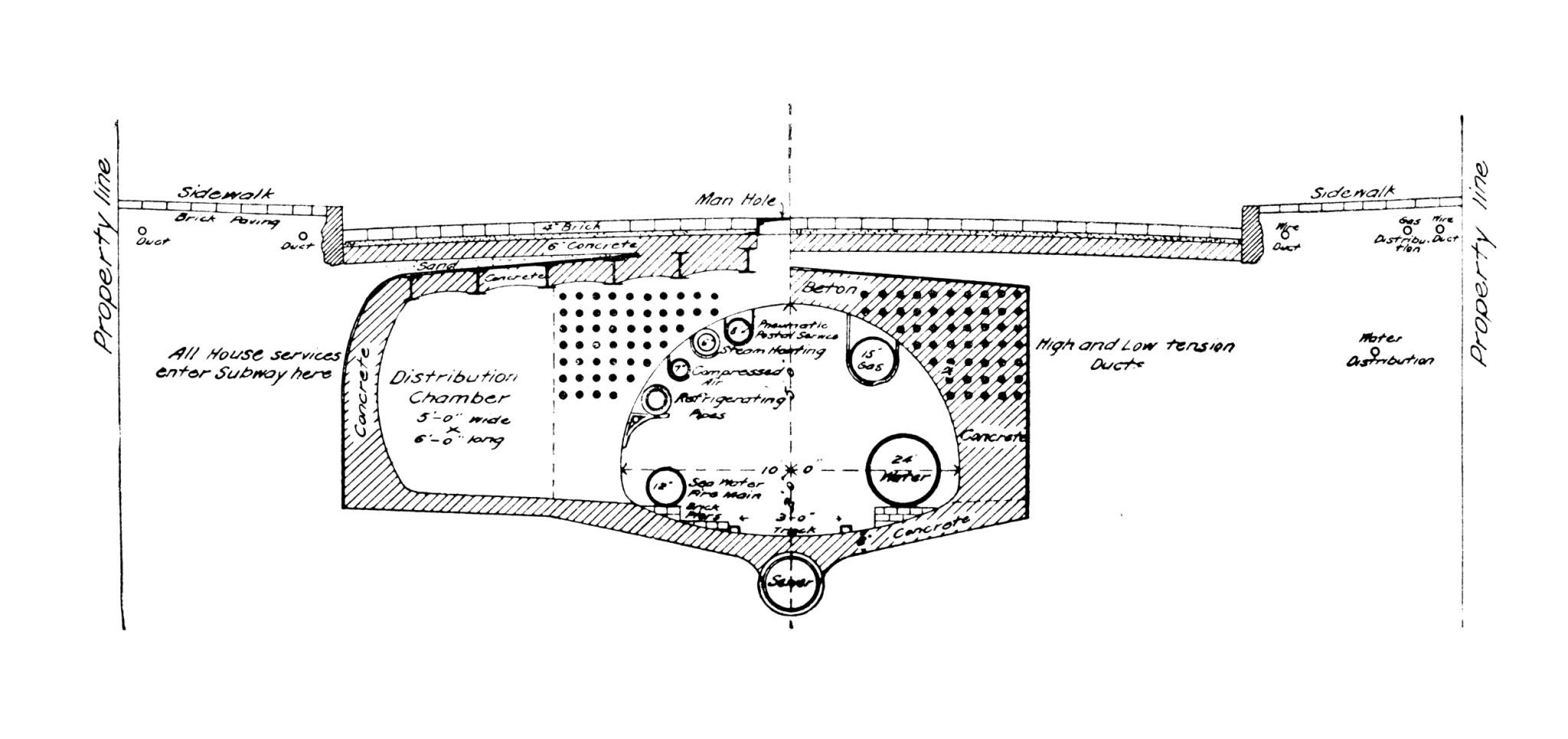

4. Groundwater Depth

Where to look: Subsurface Conditions / Boring Logs

Check: The depth to groundwater encountered during drilling.

The Red Flag: Water found at depths shallower than your deepest utility trench or excavation (e.g., 5-10 feet).

Why it matters: If you hit water, you trigger Dewatering. This requires pumps, permits, and filtration systems before you can even lay a pipe. It kills productivity and balloons costs.

5. R-Value (Pavement Thickness)

Where to look: Pavement Recommendations

Check: The "R-Value" (Resistance Value).

The Red Flag: An R-Value below 20-30.

Why it matters: R-Value measures the soil's ability to support weight under traffic.

High R-Value (50+): Good soil. You can use a thinner section of asphalt/base.

Low R-Value (<20): Weak soil. You will need a much thicker section of Aggregate Base (ABC) and asphalt to prevent the road from rutting.

6. Bearing Capacity

Where to look: Foundation Recommendations

Check: Allowable Bearing Pressure (measured in psf - pounds per square foot).

The Red Flag: Values below 1,500 - 2,000 psf.

Why it matters: If the soil is too weak to hold the building up, you will need larger footings (more concrete/rebar) or deep foundations (caissons/piles) instead of standard spread footings.

Here is the science behind Lime Treatment, often referred to as "chemically modifying" the soil.

When you see big spreaders dropping white powder on a site and massive mixers churning it into the ground, they aren't just drying the dirt; they are fundamentally altering the chemical structure of the clay. It’s essentially turning "taffy" into "concrete."

1. The Problem: The "Electric" Clay

To understand why lime works, you have to understand why clay is a problem.

Microscopic Shape: Clay particles aren't round like sand; they are flat plates, like a deck of cards spread out.

Electrical Charge: The surface of these plates has a negative electrical charge.

The Water Sandwich: Water molecules are "dipolar" (they have a positive side). The positive side of water attracts to the negative side of the clay. This creates thick layers of water between the clay plates, pushing them apart.

The Result: When wet, the plates slide easily (plasticity/mud). When dry, the water leaves and the plates collapse (shrinkage/cracking).

2. The Solution: Chemical Warfare on Clay

Lime treatment usually involves Quicklime (Calcium Oxide - CaO) or Hydrated Lime (Calcium Hydroxide) - . When mixed with wet clay, two distinct scientific phases occur.

Phase 1: Immediate Modification (The "Dry Down")

This happens within minutes to hours.

Dehydration: Quicklime is thirsty. It chemically consumes water to satisfy its own structure. This reaction is exothermic (releases heat), causing even more water to evaporate as steam.

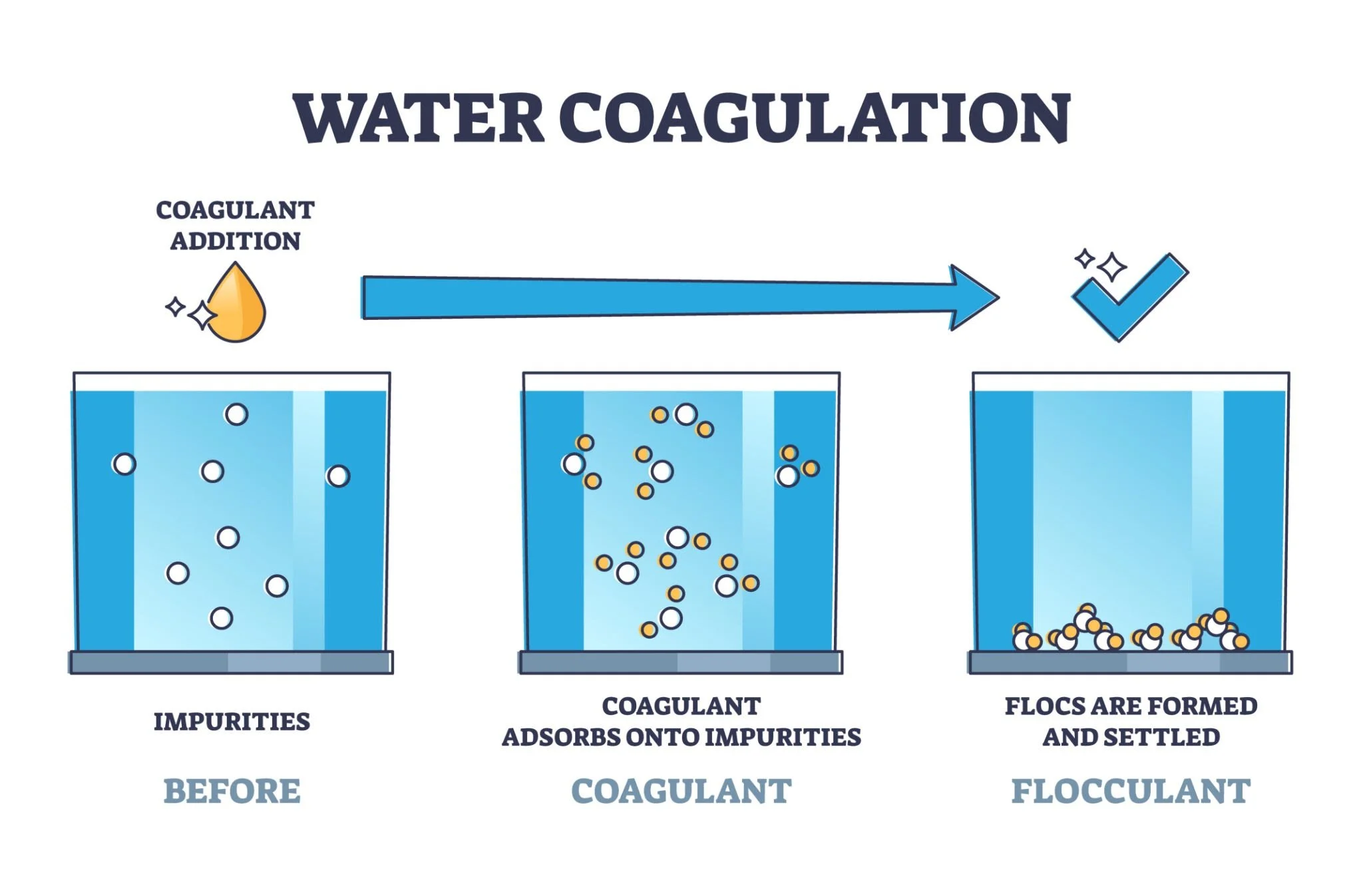

Ion Exchange (The Magic Switch): This is the key. The lime floods the soil water with Calcium ions

Clay naturally holds onto weak ions like Sodium

Calcium is a stronger ion with a double positive charge. It bullies the Sodium out of the way and latches onto the clay surface.

Flocculation: Because the Calcium charge is stronger, it reduces the electrical repulsion between the clay plates. The plates stop repelling each other and clump together (flocculate).

Texture Change: The soil instantly changes from sticky, plastic "tooth-paste" to a crumbly, sand-like texture (friable).

Getty Images

Phase 2: Stabilization (The "Cementing")

This is a slow-burn chemical reaction that happens over weeks and months (and even years).

The Pozzolanic Reaction: The high pH (alkalinity) caused by the lime essentially melts the silica and alumina naturally present in the clay.

These dissolved minerals react with the Calcium to form Calcium-Silicate-Hydrates (C-S-H) and Calcium-Aluminate-Hydrates (C-A-H).

Translation: This is the exact same chemical binder found in concrete. The soil is literally growing microscopic cement crystals that bind the particles together permanently.

3. The Result: A New Material

After treatment, the soil is no longer defined as the same USCS classification.

Plasticity Drops: The Plasticity Index (PI) often drops from 30+ (highly expansive) to below 10 (non-expansive).

Swell Potential Dies: The clay plates are chemically bonded; they can no longer push apart when water is introduced.

Strength Increases: The bearing capacity skyrockets, often removing the need for deep foundations.

4. The Risk: Sulfate-Induced Heave

There is one major trap in lime treatment science.

The Villain: If the native soil contains high Sulfates (gypsum), adding lime is a disaster.

The Reaction: The Lime + Sulfates + Water + Alumina creates a new mineral called Ettringite.

The Consequence: Ettringite crystals expand massively (up to 250% volume increase) when they form. Instead of stabilizing the ground, you create a chemical reaction that causes the ground to heave worse than the original clay.

Note: This is why the Soluble Sulfate test from your checklist (Point #3) is critical before ordering lime.

Here is the science behind Cement Treatment (often called Soil-Cement or CTB - Cement Treated Base).

If Lime Treatment is "chemical modification," Cement Treatment is "mechanical binding." While lime chemically alters the personality of the clay, cement simply overpowers the soil by gluing it together into a solid mass. It turns the dirt into a weak, lean concrete.

1. The Mechanism: Hydration (The "Glue")

Unlike lime, which requires the silica/alumina inside the clay to work, cement brings its own chemistry to the party.

The Process: When Portland cement meets water, it triggers Hydration.

The Reaction: The calcium silicates in the cement powder react with water to form Calcium-Silicate-Hydrate (C-S-H) gel.

The Matrix: This C-S-H gel grows outward like microscopic tendrils. These tendrils interlock around the soil particles (sand, silt, or clay) and harden. It doesn't matter much what the soil is; the cement forms a rigid skeleton around it.

2. Solving the Sulfate Problem

You asked about sulfates. As noted, mixing Lime with high-sulfate soil creates Ettringite (the explosive crystal). Cement can be the cure, but only if you use the right type.

The Culprit: The ingredient in cement/lime that reacts with sulfates is Tricalcium Aluminate (C3A)

The Fix (Type V Cement): Engineers specify Type V (Sulfate Resistant) Cement.

This cement is manufactured with very low levels of C3A (usually < 5%).

Without the Aluminate fuel, the sulfates in the soil have nothing to react with to form Ettringite.

The cement hardens safely without blowing up the ground.

3. Where Cement Wins: Granular Soils (Sand)

Lime is useless on sand.

Why: Lime needs clay particles (alumina/silica sheets) to react with. Sand is chemically inert (just quartz rock). Pouring lime on sand is like salting a rock; nothing happens.

Cement's Advantage: Since cement brings its own binding agent, it works exceptionally well on sandy/silty soils that lack clay content. It bridges the gaps between sand grains, creating a high-strength "pavement" layer.

4. The Trade-Off: Rigidity vs. Flexibility

There is a catch. The fundamental difference in the end product dictates where we use which method.

Lime Treated Soil: "Flexible"

Behavior: The soil remains somewhat flexible. It has "healed" its plasticity, but it can still move slightly without breaking.

Best for: Building pads and expansive clays where you want to kill the swell but keep a natural soil behavior.

Cement Treated Soil: "Rigid & Brittle"

Behavior: The soil becomes a rigid slab. It has very high compressive strength (often 300–800 psi).

The Risk (Reflective Cracking): Because it is rigid, if the ground beneath it moves, the cement-treated layer will crack rather than bend. These cracks can reflect up through your asphalt or slab.

Best for: Road bases (under asphalt) or parking lots where load-bearing capacity (R-Value) is the priority over flexibility.

Technical Approach

Question: "How does Pinnacle handle expansive soil in Arizona?"

Answer: (Use the Lime Treatment/Over-Ex content).

Question: "How do you ensure schedule certainty on data center projects?"

Answer: (Use the Predictive Safety / 4D Scheduling content).

What We Deliver

Mass Grading & Excavation – Moving 500,000 to 5+ million cubic yards per campus with GPS and 3D machine-control fleets for sub-half-inch tolerances across hundreds of acres.

Precision Building Pads – Elevated slabs and structural fill engineered for 1.5 million-pound rack loads and liquid-cooling infrastructure.

Cut-to-Fill Balance & Stockpile Management – Maximizing on-site material reuse to crush schedules and minimize haul costs in a market where every day counts.

Over-Excavation & Engineered Fill – Deep remediation for expansive Arizona soils, ensuring zero settlement under the most demanding data-center footprints.

Pioneering & Pad Certification – Final-grade certification packages that let structural concrete crews pour the day we demobilize.

Why Hyperscalers and Developers Choose Pinnacle for Earthwork

Speed – Routinely 20–30 % faster than industry averages by self-performing with the largest machine-control fleet in the state.

Accuracy – Trimble / Topcon / Leica systems on every dozer, scraper, and excavator — because AI campuses don’t tolerate rework.

Scale – Proven on 200–800+ acre greenfield sites in Buckeye, Mesa, Queen Creek, Goodyear, and Casa Grande.

Arizona Expertise – We understand caliche, expansive clays, and flood-plain challenges better than anyone — because we’ve been moving Arizona dirt for decades.

When the grid is years behind and GPUs are already on the water, the only thing that matters is how fast you can hand over a perfect pad. Pinnacle’s earthwork teams don’t just move dirt — we eliminate the bottleneck that stands between stranded chips and energized AI.

Pinnacle Heavy Civil — We grade the future. One perfectly balanced acre at a time.

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!